|

|

| |

|

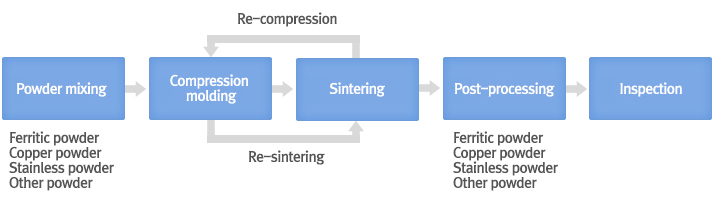

| Metal processing by compression molding of various kinds of metal powder with metal mold and special pneumatic sintering. (up-to-date manufacturing of metal machine parts)

Production of more complex shapes including cogwheel, curve, caster, etc. with narrow range of acceptable values is available. (various types of production available without post-processing)

Product shapes and sizes in one series are very even and precise. (Precise measurement)

High purity, high quality part production is available; excellent surface condition. (even component composition)

Mass production and automation of machine parts, structural parts are available. (affordable cost)

Self oil supply by containing oil within the processing. (oilles bearing, filter)

For sintered steel, case hardening, heat treatment and steam treatment are available. (quality improving post-treatment available)

No material loss from break metal during cast processing or machine processing. (it saves material costs and processing costs) |

|

| |

|

|

| |

|

| Application |

Use |

| Regular machine parts |

Cars/ machine parts / electric & electronic parts / farming machine parts |

| Porous parts |

Various oilless bushes / solid lubricant bushes / filters |

| Composite materials |

Hard metal parts(WC-Co) / electric connection parts(W-Cu, Cu-C) |

|

| |

| |

|

| |

|

|

|